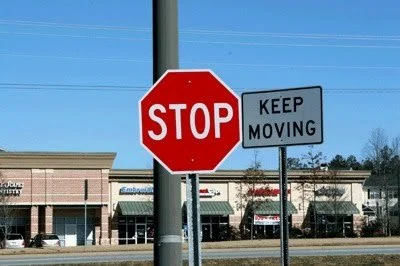

“There’s got to be a better way…”

As the supply chain has become more stable over the past year, many entrepreneurs are still confronting frustration from being unable to reliably find out the key information about shipments of product they expect to efficiently run their business. Within certain segments of the distribution industry, the normal process is to contact the manufacturer/supplier and ask them to provide an estimated time of delivery or a status update. This, in turn, elicits a call from the supplier to the shipper. Invariably the shipper then must reach out to the carrier dispatcher who then will try to reach the driver of the vehicle transporting the load. Of course, with so much of manufacturing having gone to offshore facilities, this chain of communication may also include an initial call to the freight broker to inquire about the status of the container ship arrival date, or the status of the container at the port and its anticipated placement on a drayage chassis to be moved to a hub and then hopefully head to a shipping terminal for eventual delivery.

Even more inefficient and time consuming is the scenario where within each of the supply chain elements, channels must be accessed and negotiated. The from the distributor probably starts with the supplier’s customer service contact who then has to contact the traffic coordinator within the supplier’s organization. That call then goes to the customer service contact at the shipper who likely must reach out to the dispatcher or their traffic coordinator. The request passes through so many hands, awaitin gso many responses to the one key question: “Where is our product?” Hardly an efficient model.

For those that are thinking “there has to be a better way!” … there are several software applications that allow for real time supply chain transportation visibility. The underlying architecture does rely on cooperative data exchanges between partners and with many distributors utilizing scores of supplier partnerships, the project scope considerations might be daunting. But the long term benefits, as more and more data points are made available, could be transformative to the industry. From the point of issuing the Purchase Order to the actual receipt of product into the warehouse, a dashboard could provide real time updates on the status of the order. When it is scheduled to ship, when it has been consigned, when it has hit the road, and perhaps with GPS being ubiquitous on many carrier vehicles, where it is on its journey at any time of day or night. The guesswork is now transformed into hard data. And knowing where the product is, when it will arrive and when it will be available for sale, takes the guess work on the daily or weekly sales forecast out of the equation. Even more attractive, the ability to meet customers’ expectations for information about their needs adds to the the customer service profile.

It is also expected that over time, the planning for purchase decisions and timing of purchase orders can be automated with greater accuracy and increased on time deliveries, reducing out of stock situations and improved fill rates, both key determinants of customer satisfaction. But at present, these are not inexpensive. TMS platforms require an investment, significant resource allocation, project management and continuous data maintenance. In the end, however, the investment, particularly for the large volume distributor with demanding key customers, seems prudent and warranted.

Silver Fox Consulting offers support in the key elements to building such a bridge to any real time visibility platform. With appropriate systems and processes designed to ensure data integrity, making the connections required through these platforms can offer key insights through daily dashboards well in advance of the implementation and deployment. It all starts with the relevant data available within the business’ daily transactions, metrics that should be part of management’s daily review anyway!